Automated Robotic Solutions

House of Design is leading the automation of the components industry by offering robotic work cells and full production lines that provide clients with solutions that increase output, improve quality, address labor concerns, and reduce overall costs.

In partnership with Alpine, House of Design has recently developed two automated solutions designed to revolutionize floor and roof truss production, Automated Floor Truss System and Automated Roof Truss System. In addition, House of Design offers their preplate cell as a stand-alone product for your cut-up market needs.

Request a consultation for full rate comparisons and ROI analysis.

Address Labor Needs & Costs

Increase Production

Reduce Errors

& Waste

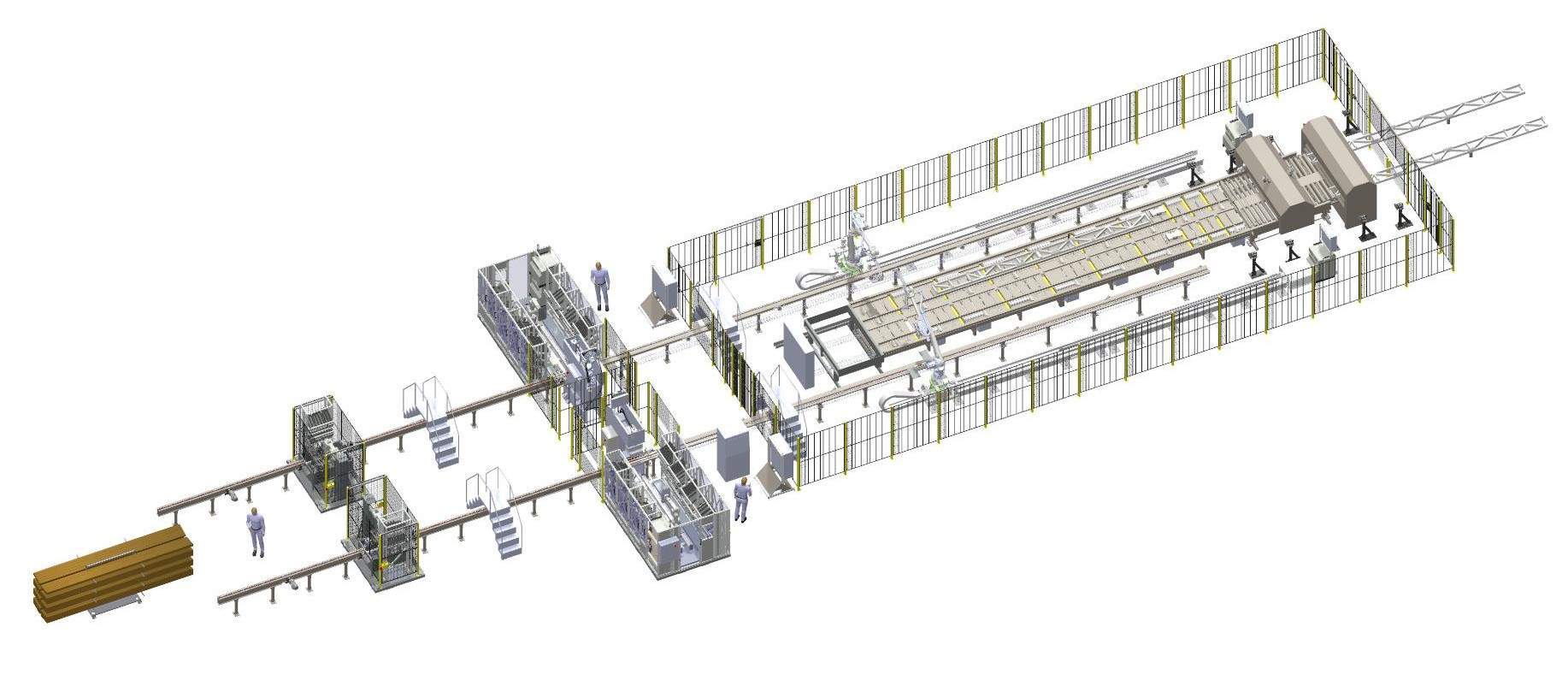

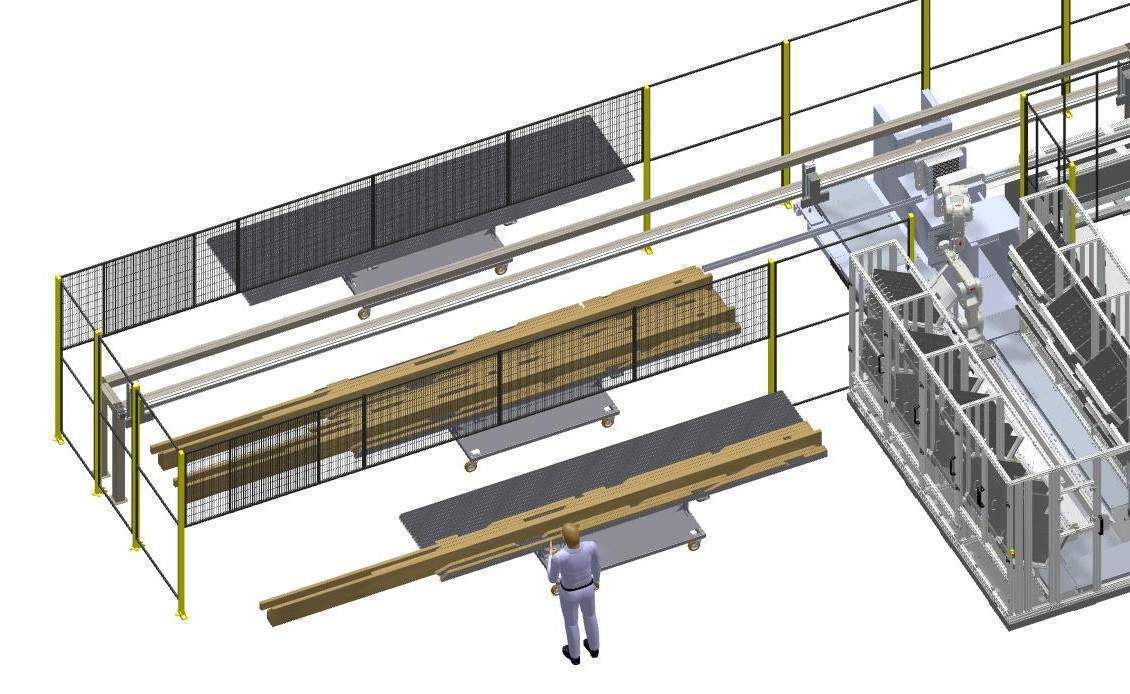

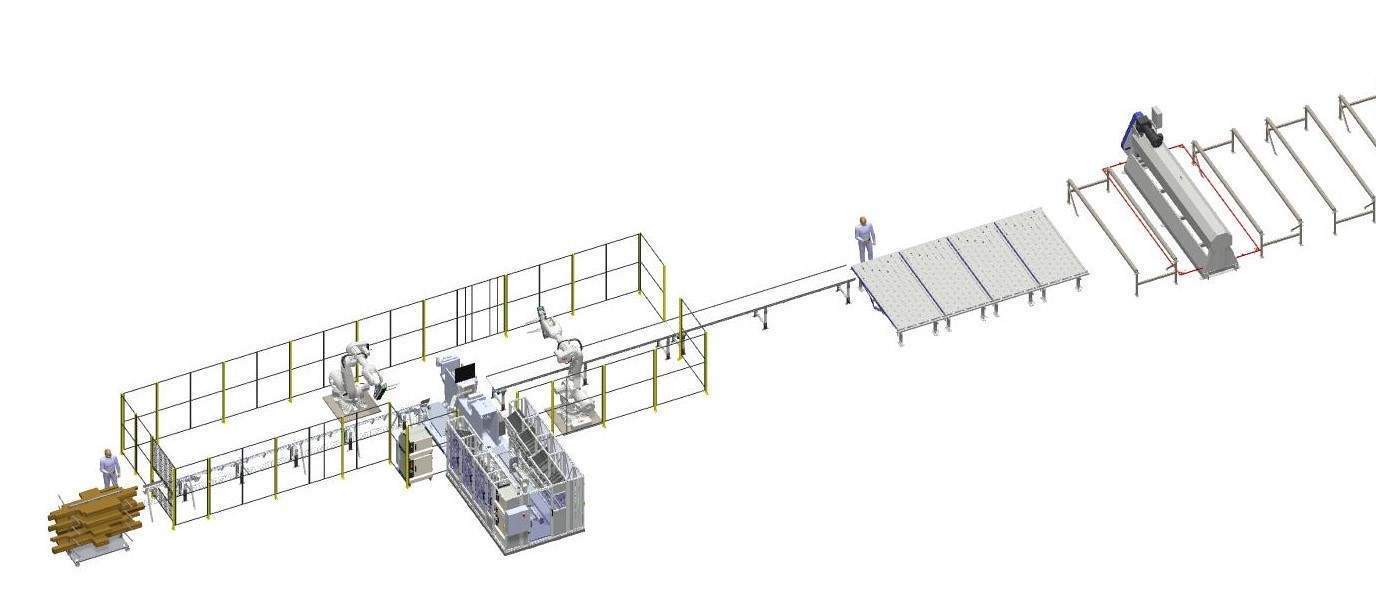

Automated Floor Truss System

Collaborative Assembly System ~ 800+ Cp/Hr with 3 operators

Two lines feeding one assembly table, two trusses ejected every time the gantry press is operated for up to 1,000+ board feet per hour.

System components:

Manual Infeeds, Splicing Stations, Preplate Stations, Assembly Stations

Alpine components sold separately:

Tables, Exit Roller(s), Finish Press

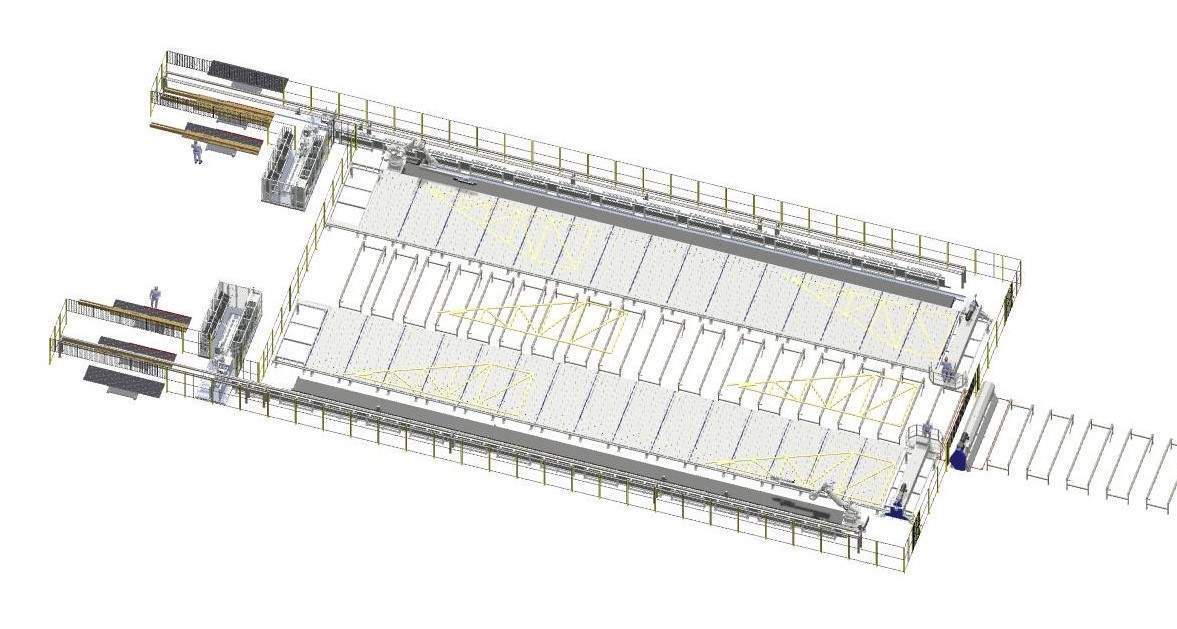

Automated Roof Truss System

Collaborative Assembly System ~ 800+ Cp/Hr with 3 operators

The roof truss system is actually two independent systems; allowing different designs to be built simultaneously. Flexibility to run only one automated line when demand is lower, providing for greater flexibility on production scheduling & optimization.

System components:

Automated Cart Infeed, Preplate Stations, Assembly Stations

Alpine components sold separately:

Tables, Exit Roller(s), Finish Press

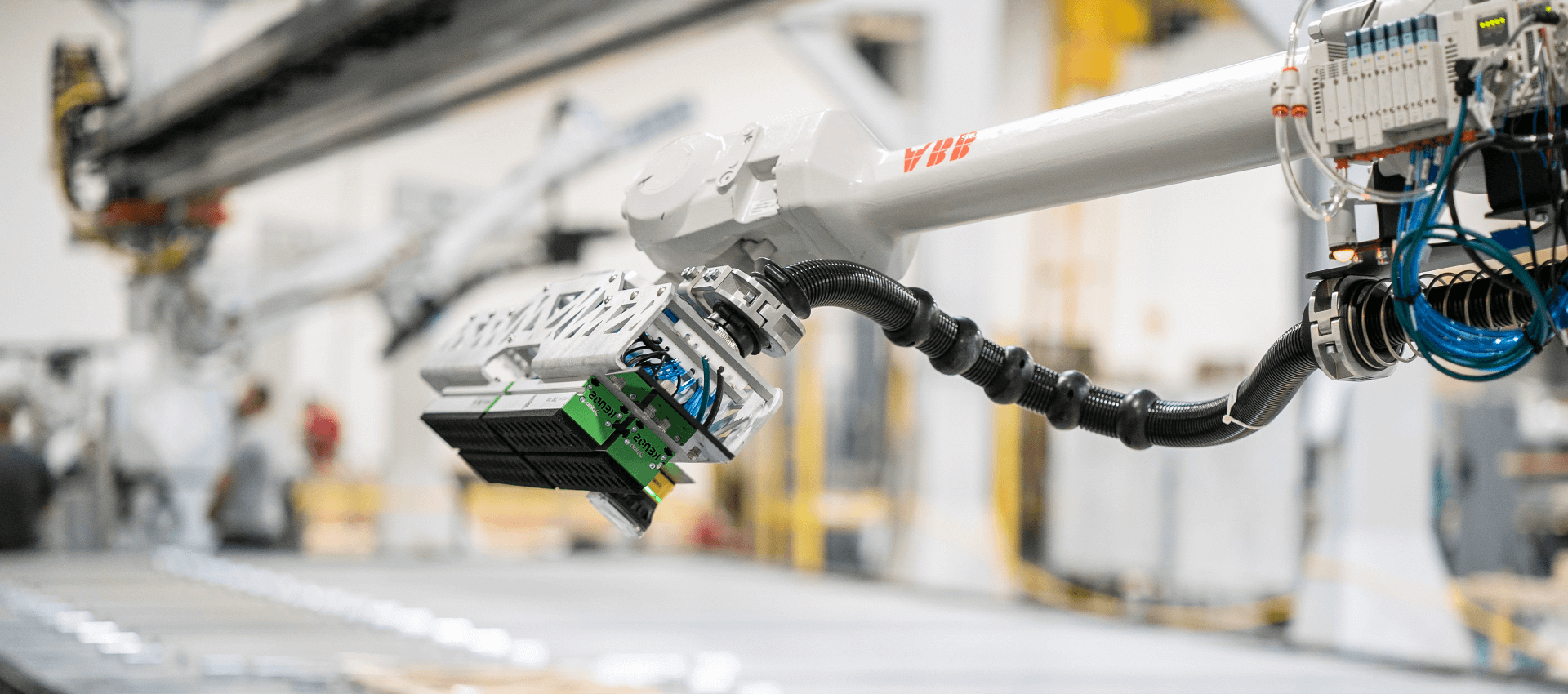

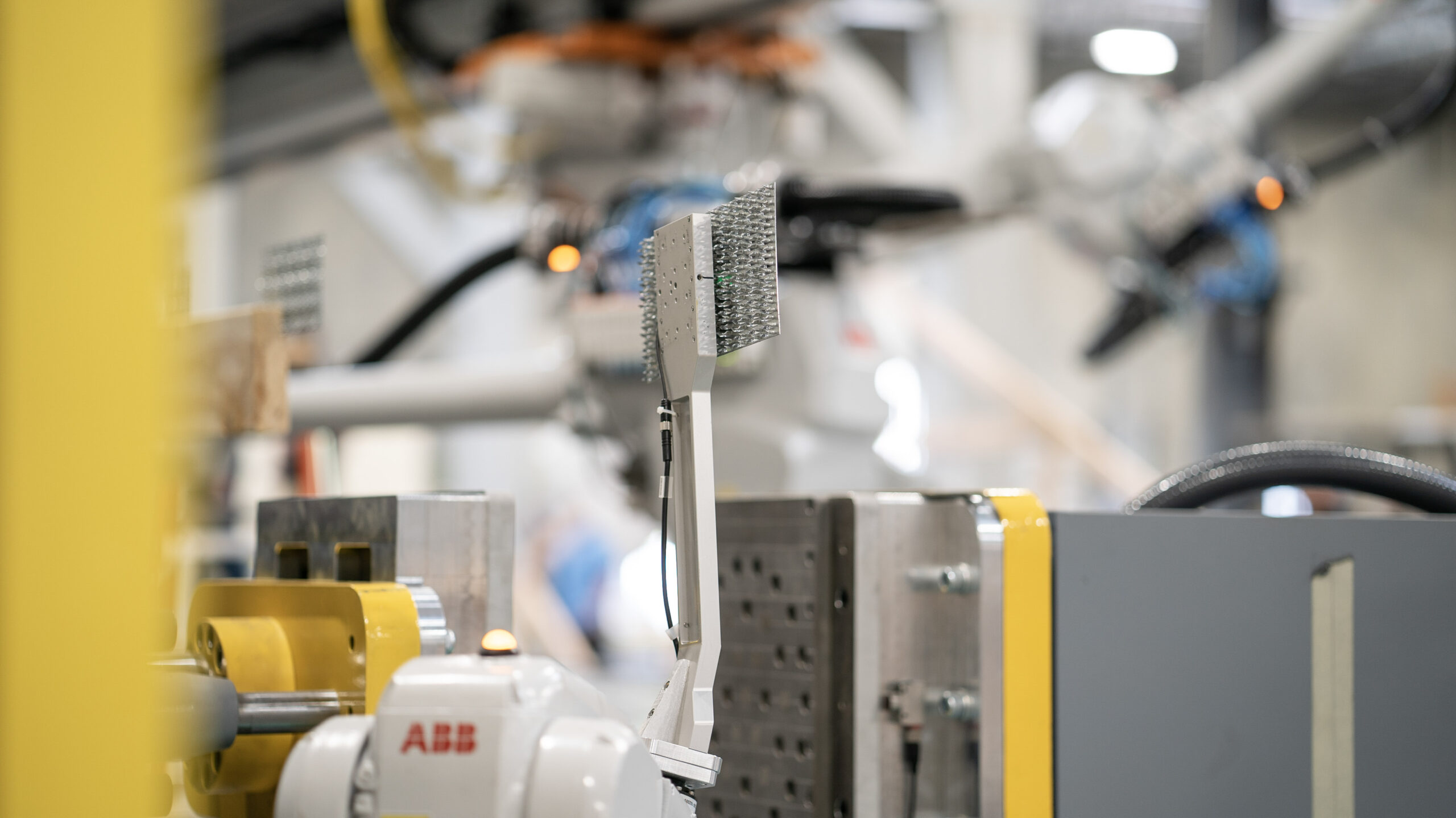

Roof Member Preplate Station

An efficient robotic solution supporting increased demand for jack and small specialty trusses. Station infeeds pre-cut roof truss members and preplates them in the correct sequence to be assembled on the table. Safer interactions, placement accuracy and reduced labor costs are some of the benefits of robotic automation. The Roof Member Preplate is an ancillary product used within House of Design’s full Automated Roof Truss System.

Learn More Literature Contact Us