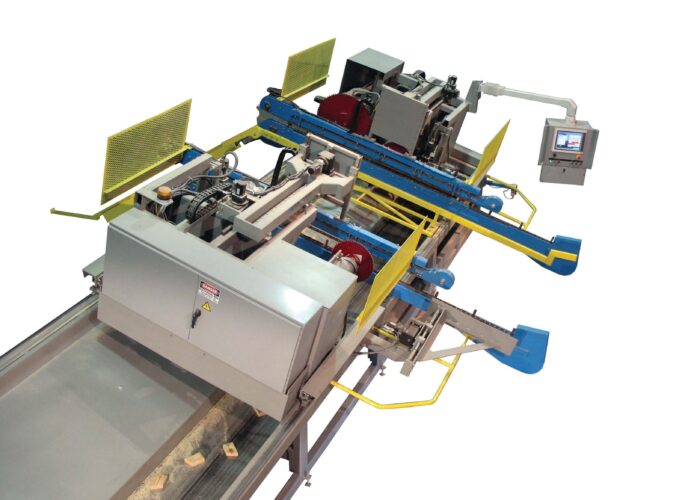

Alpine® AutoMill HP

The Alpine AutoMill HP sets the bar for outstanding performance in the component manufacturing industry. Full automation for 23 axes of motion increases setup speed and cutting accuracy, making the AutoMill HP top of its class among component saws. It features five blades to maximize the cutting range. Integrated air disc brakes stop the blades quickly and safely.

Standard Footprint: 47’-9” x 20’-3” (W x L)

*as shown

Fast &

Flexibility

The AutoMill HP’s flexibility allows you to cut the toughest jobs in the least amount of time.

Alpine Auto-Sequencing

The software knows the end of a run, and automatically sets up the angles and length for the next run.

Maximize Cutting Capability

Scarf, heel and seat cut in one pass

Features

- Maximized Cutting Range & Throughput

- Increased Speed & Setup Time

- Versatile with Two Operational Modes

- Saw Production Reporter

- Product Support

Equipped with five carbide tipped blades that last longer than a standard steel tip blade. Integrated air disc brakes stop the blades quickly and safely. Three-cut scissor bottom chords can be cut simply. The saw will make the scarf, heel and/or seat cut in one pass.

Full automation for 23 axes of motion increases setup speed and cutting accuracy. Accurate to ½ of a degree, and 1/16 of an inch at centerline

Automatic or semi-automatic operation can be used to best meet the demands and flexibility required by your production schedule.

The ability to create customizable data reports to measure your efficiency

Our equipment is backed by a highly trained support team ready to assist you with any specific equipment needs. Please call (800) 755-6005 or email our experts at machinerysupport@alpineitw.com for onsite service or technical phone support.

Specifications

| Cutting Capability | ||

|---|---|---|

| 2×3 in. to 2×12 in. | (Lumber upright on material conveyor dogs) | |

| 3×2 in. to 6×2 in. | (Lumber lying flat between material conveyor dogs) | |

| Length | ||

| Manual Mode | 14 in. (90-90) to 20 ft. (2×4 in.) | |

| Auto Mode | 18 in. (90-90) to 20 ft. (2×4 in.) | |

| Cut Types: | • Chords • Scarfs • Heels • Seat Cuts | |

| Saw Blade | Head 1 | 20 in. Carbide Tipped |

|---|---|---|

| Head 2 | 18 in. Carbide Tipped | |

| Head 3 | 18 in. Carbide Tipped | |

| Head 4 | 18 in. Carbide Tipped | |

| Head 5 | 32 in. Carbide Tipped | |

| Motor RPM | Head 1 | 3450 |

| Head 2 | 3450 | |

| Head 3 | 3450 | |

| Head 4 | 3450 | |

| Head 5 | 1725 | |

| Controller | PC | Industrial PC w/ Windows 10 Operating System |

| Monitor | 22 in. Flat Panel (Touch-Screen Optional) | |

| Communications | Ethernet | |

| Operating Temperature | 32°F to 104°F (0° to 40° C) | |

| Humidity | 10 – 95%, NON-CONDENSING | |

| Max Altitude | 6500 ft. | |

| Shipping Weight | 18,000 lbs. |

| Left or Right Hand Refuse System |

| Touchscreen Monitor |

| Label Maker |

| AutoMill, AutoMill RS, AutoMill SC, AutoMill HP |

| Emergency Stop: | Pushbutton, safety cable around 3 sides |

|---|---|

| Safety Compliance: | ETL listed panels |

| Labeling: | Trilingual (English, Spanish, French) |

| Carriage movement: | Horn (85db) and flashing light |

| Guards: | Metal guards to protect from flying blocks |