AutoSet Plus

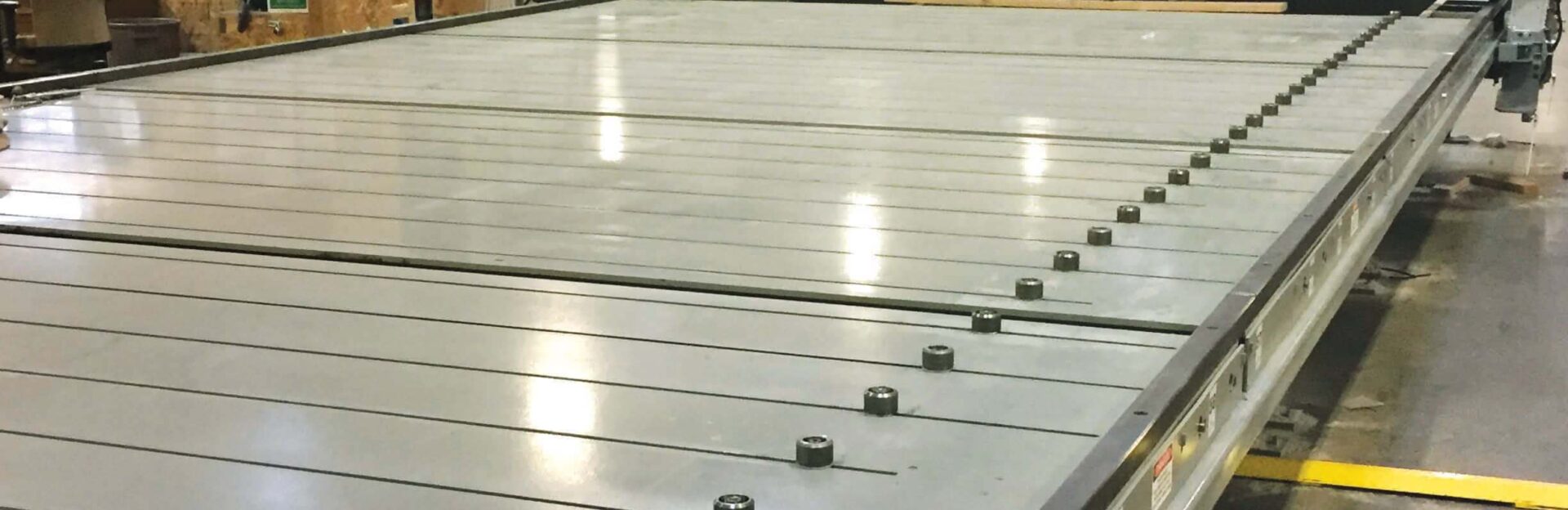

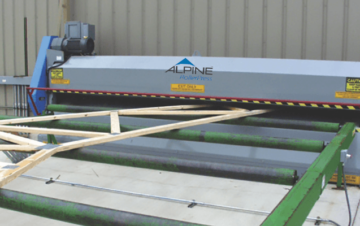

Alpine’s AutoSet Plus is the latest product in the company’s history of innovative truss table automation. AutoSet Plus contains updated automation technology enhancing our customer’s production. With set up in less than 25 seconds, this computer-controlled jigging system is engineered to be efficient and accurate. The automated steel pucks give workers the ability to keep a consistent pace throughout their shift, with higher accuracy and reduced employee fatigue. Fast, consistent production results in reduced labor costs and quicker turnarounds.

Standard Footprint: 18’-7” x Customer specific x 7’- 6” (W x L x H)

*as shown

Reliable

Engineered to be accurate, efficient and durable

Quality Production

Fast, consistent production with reduced labor costs and quick turnarounds

Ease of Operation

Easy to learn, use & maintain

Features

-

Computer-controlled system

Features on-screen graphics, directional prompts and advanced diagnostics

-

Superior quality jigging system

Durable steel top with quick setup time and precision laser cut table-top

-

Compatibility

SmartView and Windows 10 compatible.

-

Horn & Light Signal

To alert the assemblers when a group of lift-outs is about to operate.

-

Lift-out detection

To avoid being hit with the gantry.

-

Tri-lingual interface

Operators can run the table in English, Spanish or French

-

Product Support

Our equipment is backed by a highly trained support team ready to assist you with any specific equipment needs. Please call (800) 755-6005 or email our experts at machinerysupport@alpineitw.com for onsite service or technical phone support.

Specifications

| Gantry Roller Face Width | 14 ft. 7 in. |

|---|---|

| Gantry Overall Width | 18 ft. 7 in. |

| Gantry Travel Speed | 140 in./min. |

| Table Length (Per table) | 7 ft. 1 in. |

| Table Width (Between Rails) | 14 ft. 3 in. |

| Maximum distance between top and bottom automated pucks | 12 ft. 6 in. |

| Truss Jigging Setups/Groups | 1 to 4 groups per system |

| Air Requirement | 2 CFM per liftout at 100 PSI (when activated, not a constant draw) |

| Operating Temperature | 32° to 104° F |

| Amperage Requirements | 480 V, AC, 3 Phase (Customer must provide transformer if other than 480V-3PH) • 25 Amp per Gantry • 15 Amp for the Controller Box • 20 Amp per 16 Automated Axis |

| Foundation Requirement | ≥6” thick reinforced concrete |

| Languages | English, Spanish, French |

|---|---|

| Voltage | 480V |

| Table width | 14 ft.-3 in. |

| Maximum span between automated pucks | 12 ft.-6 in. |

| Air requirement | 2 CFM @ 100 psi per liftout |

| 4 automated pucks, 4 manual pucks, 7 baseline |

| 8 automated pucks, 7 baseline |

| Additional computer stations |

| SmartView |

| Additional gantry heads |

| Emergency Stop: | Pushbuttons |

|---|---|

| Safety Compliance: | ETL listed panels |

| Labeling: | Trilingual (English, Spanish, French) |

| Press Movement: | Horn (85db) and flashing light |