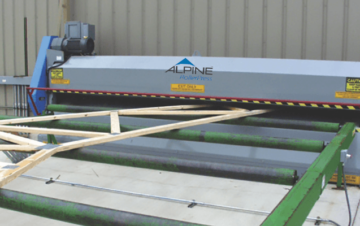

Alpine® FloorMaster

The Alpine FloorMaster is an innovative machine for truss assembly. This floor truss production equipment minimizes material handling through its power flipping and lift-out features, making floor truss production easy.

Standard Footprint: 63’-3” x 10’-6”

*as shown

Improve Productivity

Reduce labor costs by leaving the hard work to the FloorMaster. Material handling is minimized by the FloorMaster’s standard flipping and power lift-out features.

Durable &

Versatile

The FloorMaster floor truss machine is renowned for its strength in the industry. Automatic depth clamping feature makes it extremely versatile too.

Safety

Safety is integrated into each component of the Alpine FloorMaster. The Emergency Stop push bars, scanner and yellow paint for awareness are a few examples.

Features

-

Automatic Depth Clamping

Alpine auto clamping means no setup is required for truss depth. Each jigging stations has its own set of controls. The FloorMaster also has a variety of lumber stops and clamp arrangements. Pneumatic clamping is uniquely mounted above and below the tabletop to permit easy truss handling.

-

Trackless Roller Gantry

The FloorMaster trackless gantry features a powerful 10 hp gear motor driving a 24-inch roll through a double 80 chain, assuring smooth & consistent operation, and a long life.

-

Ease of Operation

The standard pneumatically controlled truss lift-outs for easy truss ejection and stacking. The truss is also power flipped between pockets reducing employee fatigue and risk of injury.

-

Operation Modes

The standard model consists of up to two stations and two modes of operation for truss fabrication. Group mode is for long trusses up to 40’. A single mode separates the controls into two stations for trusses up to 10’ per station.

-

Product Support

Our equipment is backed by a highly trained support team ready to assist you with any specific equipment needs. Please call (800) 755-6005 or email our experts at machinerysupport@alpineitw.com for onsite service or technical phone support.

Specifications

| Truss Depth | 12 in. – 24 in. (0.3 – 0.6 m) |

|---|---|

| Truss Length | Up to 40 ft. (12 m) |

| Truss Thickness | Up to 3.5 in. (0.025 m) |

| Overall Length | 64 ft. (19.5 m) |

|---|---|

| Overall Height | 11 ft. 4 in. (3.5 m) |

| Overall Width | 10 ft. 4 im (3.2 m) |

| Table Length | 40 ft. (12.2 m) |

| Table Height | 2 ft. 7 in. (0.7 m) (Adj. 2’4″ to 2’10”) |

| Table Width | 6 ft. 8 in. (2 m) |

| Roller Diameter | 24 in. (0.61 m) |

| Air System | ½ in. N.P.T., 15 CFM @ 120 psi |

| Power | 480V, 3⌀, 60 Hz, 12A |

|---|---|

| Motor Speed | 1750 rpm |

| Gear Radio | 18.7:1 |

| Sprockets Tooth | 14 & 52 |

| Gantry Speed | 158 ft./m (0.8 m/s) |

| Ejection | Side eject |

|---|---|

| Table width | 6 feet 8.5 inches |

| Table height | 29 inches + 5 inches for setting optimal working height |

| Table surface | ½ inch steel top, supported by a steel channel frame |

| Roller | 24 inches |

| Drive motor | 3-phase, 10 horsepower soft start motor |

| Speed | 160 feet per minute |

| Air requirement | 15 CFM at 120 psi |

| Camber | 0.625 inch over 40 feet |

| Truss Dimensions | Maximum length: 40 feet |

| Range of depth | 12–24 inches |

| Labeling | Trilingual Interface (English, Spanish and French) |

|---|---|

| Safety Compliance | ETL listed panel |

| Scanner | Safety scanner to detect items on the tabletop |

| Emergency Stop | Pushbuttons, Safety Bar |