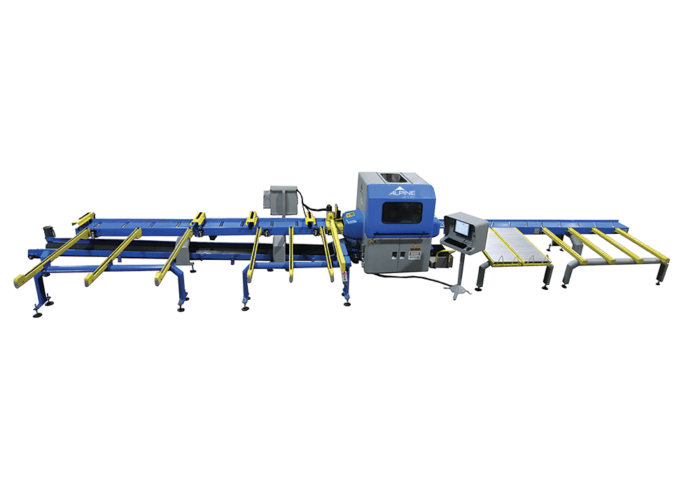

Alpine® Linear Saw 4.0

The Alpine® Linear Saw (ALS) 4.0 takes cutting to the next level reducing labor, maximizing production and increasing your bottom line. Designed for production efficiency, the ALS 4.0 requires only one sawyer for operation, and features an optional automated infeed system, beveling capability and wall panel marking. The fully enclosed cutting center keeps the operator clear of dust and moving parts.

Standard Footprint: 42’– 8” x 12’–10” (W x L)

*as shown

Maximize Productivity

The ALS 4.0 configuration is system engineered for your needs to help maximize plant operations, productivity, material flow and reduce labor.

Reliable

First developed in 2002, the ALS has evolved over the years to optimize efficiencies with a proven reputation of performance.

Fast &

Accurate

Superior & accurate cutting up to a 1/16” of an inch helping reduce re-cuts and increase productivity.

Features

- Superior & Flexible Cutting with One Saw

- Configurable System to improve Material Flow

- Manual Roll case infeed, Automated Live Deck or Ranger Infeed System

- Inkjet printer

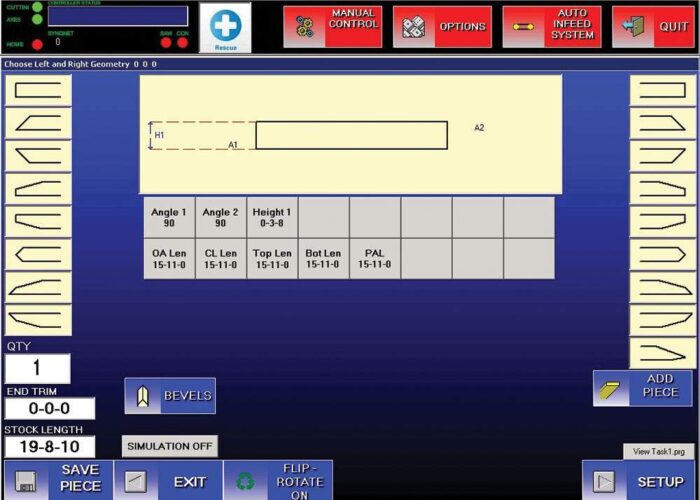

- MaxxiMizzer Software

- Easy to Use & Intuitive Operator Workstation

- Product Support

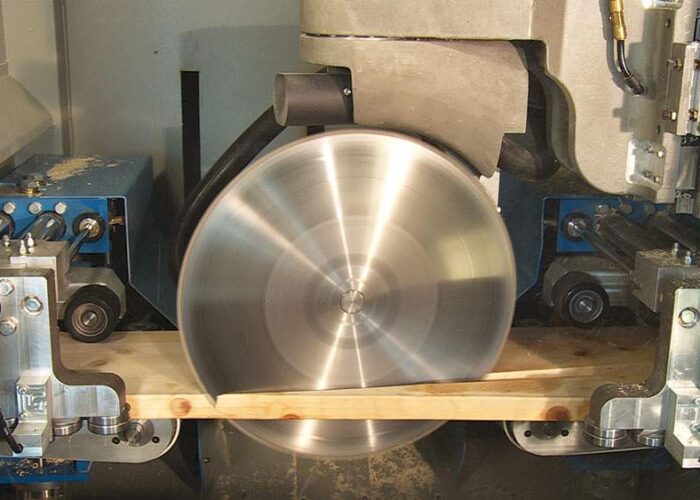

Cuts accurate, quality components helping to reduce re-cuts and improve productivity at the assembly station. Capable of cutting a variety of component types including chords, webs, scissor bottom chords, wedges, and sliders. A Beveling Axis can be added to cut bevels and ripped valley bottom chords.

The ALS is engineered and optimized for your plant’s needs. The ALS outfeed can be configured left to right, right to left, and front or rear-facing.

Optional Automated Live Deck (8’ or 16’) or Ranger Infeed System continuously feeds lumber into the saw increasing productivity.

Marks all the boards including small parts, improving assembly time.

Nests cuts, optimizes lumber usage, and reduces waste. Supports flexible Truss by Truss or batch cutting methodology.

Simple icons, featuring automatic or semi-automatic sawyer operation modes.

Our equipment is backed by a highly trained support team ready to assist you with any specific equipment needs. Please call (800) 755-6005 or email our experts at machinerysupport@alpineitw.com for onsite service or technical phone support.

Specifications

| Lumber Size Range | Min | Max | |

|---|---|---|---|

| Width | 2.38”(64mm) | 14”(355mm) | |

| Thickness | 1.38”(35mm) | 1.77”(45mm) | |

| Length | 36”(915mm) | 24’(without additional support) | |

| Chords • Webs • Scissor bottom chords • Wedges • Sliders |

| Single and double beveled ends ( when saw is equipped with optional bevel axis ) |

| Ripped valley bottom chords ( when saw is equipped with optional bevel axis ) |

| Floor truss webs ( when saw is equipped with optional bevel axis ) |

| High Performance (H/HB) | ||

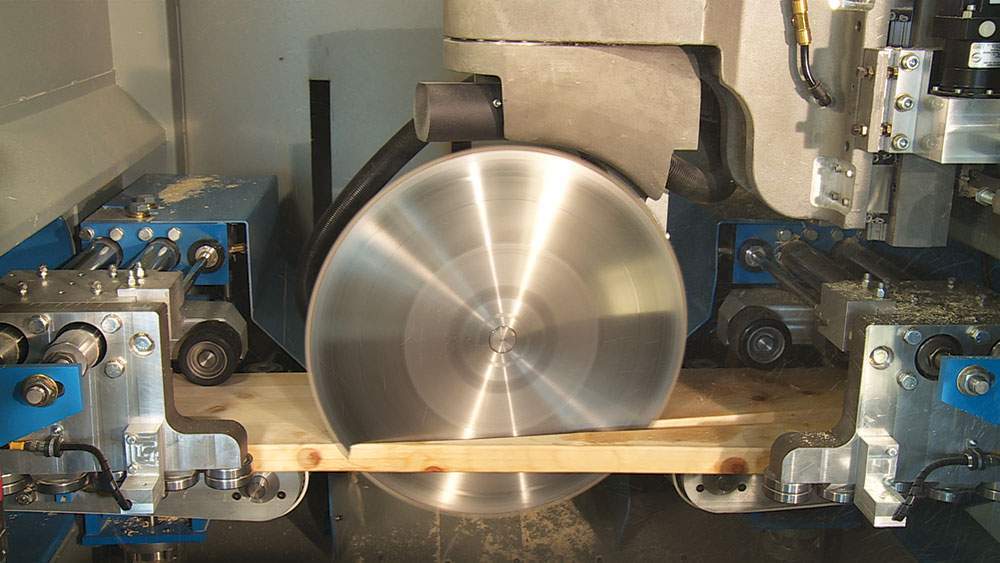

| Saw Blade | Diameter | Custom 20.5″ |

| Blade Motor | Max RPM | 2800 rpm |

| Infeed (L1-axis) |

Accuracy Max Speed |

±1/16” 160 in/sec |

| Outfeed (L2-axis) |

Accuracy Max Speed |

±1/16” 160 in/sec |

| Translation Cutting (L1-T1) | Max Speed | 28 in/sec |

| Angle (A-axis) |

Travel Accuracy |

-0° to +270° ±0.05° |

| Bevel (optional) (B-axis) |

Travel Accuracy |

5° (bevel) to 70° (very sharp bevel) ±0.05° |

| Traverse (T-axis) |

Travel Accuracy |

-10” to +14” 0” references the fence |

| Vertical (Z-axis) |

Travel Max Speed |

7 ½” 13 in/sec |

| Controller |

PC Monitor Communications |

Industrial PC w/ Windows 7 Professional Operating System 22” flat panel Ethernet |

| Operating Temperature | 41°F to 104°F | |

| Humidity | 10-95%, non-condensing | |

| Max Altitude | 6500′ | |

| Shipping Weight | 3500 lbs | |

| Foundation Requirement | ≥4” thick reinforced concrete | |

| Voltage Draw | 480VAC 3PH 60A, WYE, 60Hz/FLA 48 A @ 460VAC | |

| Air Draw | 25 CFM @100 Psi |

| Beveling |

| Automated Infeed (8’ or 16’) |

| Ranger Infeed System |

| Rear-Facing Outfeed |

| Right to Left Configuration |

| Waste Incline Conveyor |

| Touchscreen Monitor |

| Wall Panel Plate Marking |

| 275, 276, 286, 4.0 |

| Emergency Stop | Pushbuttons |

|---|---|

| Interlock | Safety rated interlock on front door |

| Safety Compliance | ETL listed panels |

| Labeling | Trilingual (English, Spanish, French) |

| Saw blade | Enclosed cutting area |