How do you get a new component manufacturing business up and running at a competitive speed as efficiently and quickly as possible, on the eve of a global pandemic, when you’re short on startup capital? The two-part answer is simple: Alpine® and STITCHER®.

Lance Keller knows the construction industry. He has been in it all his life. So when he decided to start a building component business from the ground up in early 2020, he understood the necessity, value, and benefits of aligning with experts. First, he partnered with Jeff Popour, who brought an in-depth understanding of component design and manufacturing, and together they formed a partnership between United Southwest Components and Alpine, which introduced them to STITCHER. Within months they were up and running at a rapid pace.

“The Alpine reputation and track record was impressive. They have delivered. STITCHER is a super powerful tool, a real game-changer.” – Lance Keller, Owner, United Southwest Components

United Southwest Components is using STITCHER to win bigger jobs in less time.

KEY SUCCESS POINTS

With STITCHER, Alpine’s unique design software technology, United Southwest found that projects which would have taken 3-4 days to complete were accomplished within just a few hours. STITCHER is easy to use, allowing even inexperienced users to become highly productive in a very short time. Before long, United Southwest was getting designs out in advance of deadlines.

Alpine worked closely with Lance and Jeff, helping them channel start-up resources into performance by being strategic with overhead. Because Alpine’s systems integrate with equipment from third-party manufacturers, United Southwest was able to bring used equipment online in a way that produced with seamless efficiency. This proved to be critical, as the other potential resource was only able to integrate with its own equipment.

“STITCHER has changed the way we design. We’re much more accurate and more efficient, producing bids that reflect buildings in their entirety. The larger the project, the more time we save.” – Jeff Popour, Partner/GM, United Southwest Components

IMPACT

Given the accuracy and efficiency of STITCHER and its ability to produce bids that reflect each building’s complete design, United Southwest was quickly able to compete and win large jobs with multi-story buildings, even when competing against much larger companies. In fact, as Lance Keller points out, “Plants much larger than ours are not capable of doing as much business as we are.”

Alpine® helped United Southwest Components gain the ability to: 1) more accurately bid large jobs, 2) bring inexperienced designers up to speed so they can be productive quickly, and 3) control start-up overhead.

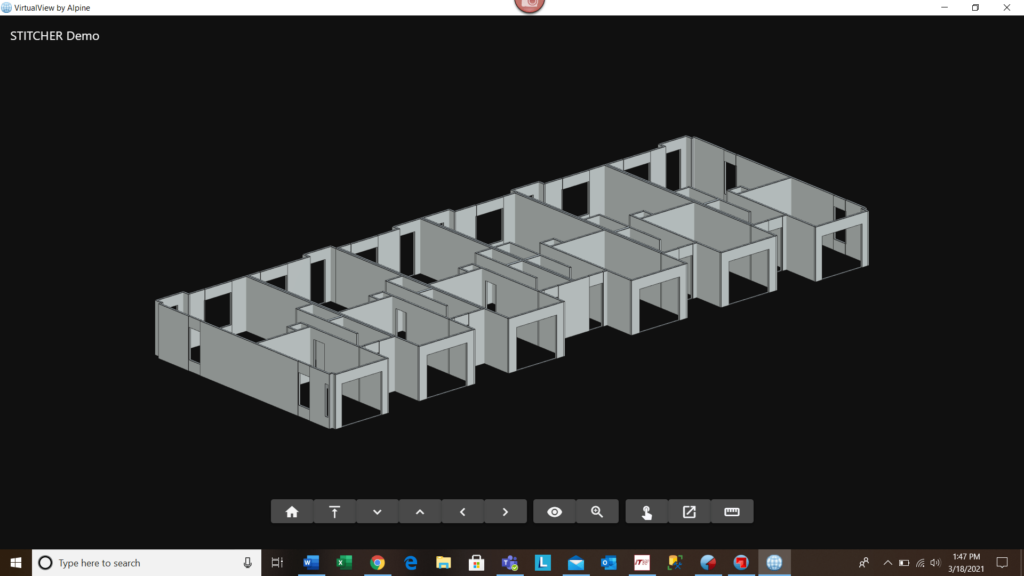

About STITCHER

STITCHER takes 2D plans to 3D models by making processes like capturing walls and openings faster. The automatic selection and measurement tools help to analyze the varying styles of a builder’s plan, identify the building envelope, and automatically fill in the walls, openings, and fixtures. Depending on your type of plan, STITCHER® can save up to 95% of the plan input time, with an average savings of 75%, leading to more accurate bids and finished/approved layouts.