eShop Plant Management Software

Gather valuable production data, eliminate paper, and take control of the component manufacturing plant with the Alpine® eShop plant management system. Schedule and track jobs at customized production stations, making on-the-fly adjustments as needed. Shop employees can quickly log valuable production data to provide real-time status updates, while viewing paperless production drawing info to support their work. eShop manages roof truss, floor truss, and wall panel production activity in one integrated platform-no need to install and train on multiple systems. eShop integrates directly with all Alpine equipment, and select third party equipment, to further optimize the data collection process. Management can see the live status of every item moving through the plant and analyze historical data to understand production trends and drive efficiency.

Easy Integration

Integrates with all Alpine and

select third-party equipment

to optimize the data collection

process.

Live Updates

See every item moving through

the plant and analyze historical

data to understand trends and

drive efficiency.

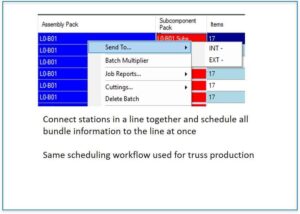

Ease of a Single System

Manage roof truss, floor truss,

and wall panel production

activity on one platform – no

need to install and train on

multiple systems.

Features

-

Improve Costing

Calculate actual labor and material cost associated with every component produced in the plant.

-

Paperless Plant

Reduce paper usage in the plant with digital displays of cutting and assembly data for shop employees.

-

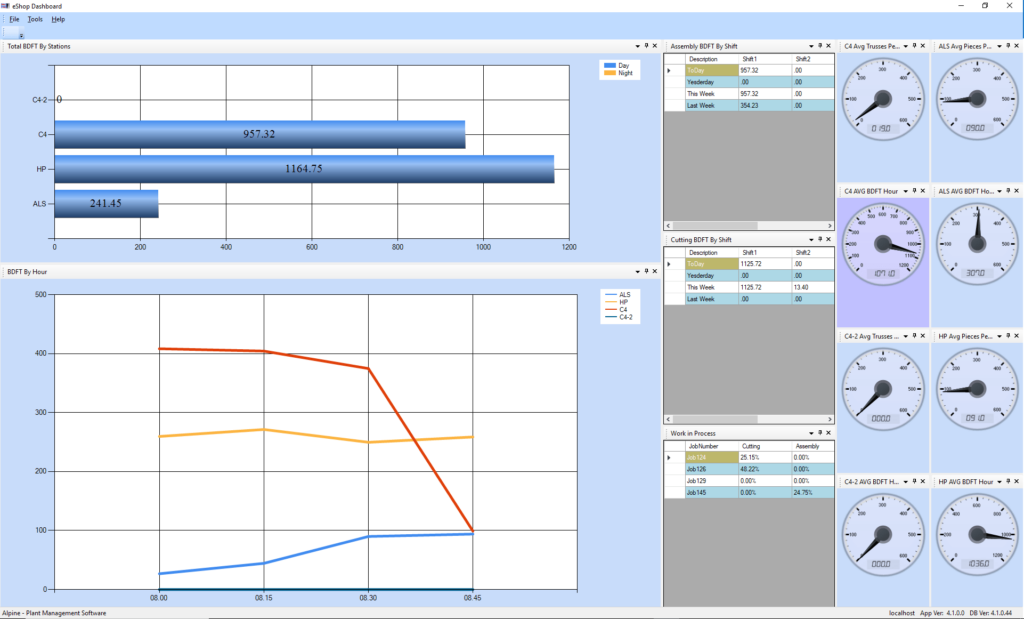

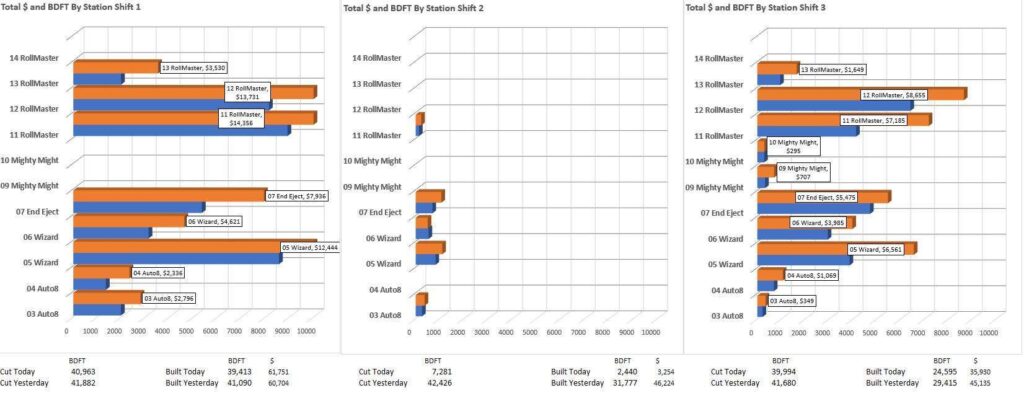

Real-Time Production Tracking

Track every piece, plate, and component moving through the plant with detailed production information logged in real-time.

-

Seamless Integration with Automated Equipment

Alpine equipment, and select third-party machines, automatically report back detailed production information to the eShop database, resulting in accurate production metrics with no disruption to the cut and build process.

-

Manage All Shop Activity

View plant-at-a-glance overview, showing live activity at each station.

Keep your plant running smoothly with on-the-fly adjustments available on every station.

-

Production Insights

Report and analyze years of historical production data to help identify trends and optimize your process.

-

Product Support

Alpine is known for its superior helpdesk and service. We’re ready to help whenever you need it. Please call (866) 237-2878 or email us at helpdesk@alpineitw.com.

Structural Engineering Support Alpine Academy FAQ Literature