Quality control starts before the first piece of lumber is set into motion. Every employee at each phase of component design and manufacturing plays a critical role to help avoid costly repairs, potential frustration, and additional workload. As an engineer that has seen many repairs, here are a few easy tips to catch a problem before it happens.

Truss Designers: Consider A Symmetrical Design

Having to replace or repair even one truss in the field causes significant disruption for everyone involved. During installation, for example, the position of the truss can accidentally be flipped or reversed. If not caught immediately, it will be both difficult and costly to pull the truss back out. The first line of defense is with design. When appropriate, design trusses symmetrically to improve field installation, paying close attention to the lumber and connector plates. This is especially true for large multiply girders that are asymmetrically loaded. A symmetrical truss can be flipped during installation without impacting the structural integrity, an asymmetrical truss cannot. With a few small adjustments in the webbing and/or selecting a larger plate size, the issue of flipped (or reversed) trusses is easily avoided, ultimately improving installation speed, and saving money (see Table 1).

Sawyers & Assemblers: The Quality of Lumber

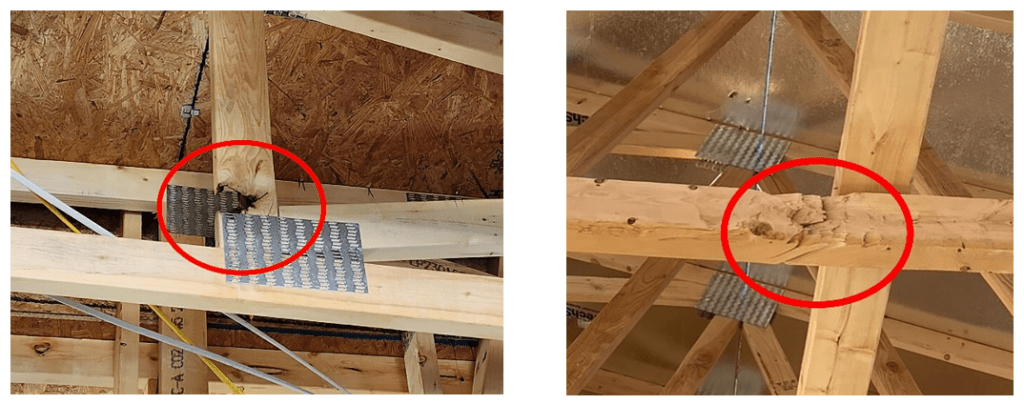

Poor quality lumber will also lead to costly repairs if not caught before installation. There are a few check points where the quality can be flagged. A sawyer will often have the first opportunity to check the lumber before it is cut and cull the final truss members of any problem areas. It is important to remove any weak portions at or near where the piece will be cut as these defects weaken a truss (see Figure 1). Removing lumber with large knots, large amounts of wane, as well as low-grade lumber will help ensure the truss’ integrity.

Poor lumber quality will also impact the quality of the connector plate embedment. When trusses are assembled at the table, there may be lumber defects located at or near the joint where the plate will be embedded. This can impact the tooth holding capacity of the connector plate. Assemblers should also review the middle of the lumber for large knots, wane, and/or low-grade lumber that could potentially weaken a truss. If a defect is identified, requesting a new truss member will help prevent costly repairs in the field. For more information, there are additional resources provided by Western Wood Products Association (WWPA) on how to visually assess lumber.

Figure 1. Two install examples of poor-quality lumber that impacted the integrity of truss members.

When trusses are delivered to a job site, they need to be checked for potential damage that may have occurred during delivery. Trusses are made up of parts assembled and held together at joints by connector plates; they are not solid members. If a truss is not properly handled, damage can easily occur while loading and unloading. If damage is identified, the site foreman should be informed prior to the truss being rolled off the truck or installation. The truss will need to be set aside at the job site and flagged. Installers will also need to be informed of the potential damage and a repair may be needed before placing the truss on the building. Communication is key. As a best practice, trusses should be inspected before and after they are delivered to a job site. Looking for damage, such as broken and/or chipped lumber (i.e., chords and webs). Also, check for any loose, torn, wrinkled, or lifted plates. If defects are identified, do not try to install the truss. Notify the site foreman or manager and set the truss off to the side. It becomes more complex to fix an installed truss compared to one on the ground. Component manufacturers will often include a document with each job, the BCSI Summary Sheet. This is written by the Truss Plate Institute (TPI) covering best practices for proper handling, installing, and bracing of trusses. The BCSI Summary Sheet is an essential guide for component manufacturers, truss installers, contractors, and builders of record.

Truss Installers

Truss installers are the last defense for flagging potential defects in a truss. They need to be careful to identify issues before sheathing, especially if a damaged truss cannot be repaired. After sheeting, the financial and scheduling impact of replacing or repairing a truss increases significantly. Spending time to recognize and correct potential problems before installation is a wise investment for component manufacturers. It is more cost-effective to take a little extra time and diligence during each phase. Quality control relies on each phase of truss design, manufacturing, and installation, and is a critical responsibility for every team member. If a problem does arise in the field and before attempting a repair, contact Alpine’s Structural Engineering Team for support. Alpine® offers 24-hour response time on engineering services as well as seasoned professionals in assessing the structural capabilities and requirements of roof and floor trusses for construction applications. They will be able to assist in finding the least costly solution.