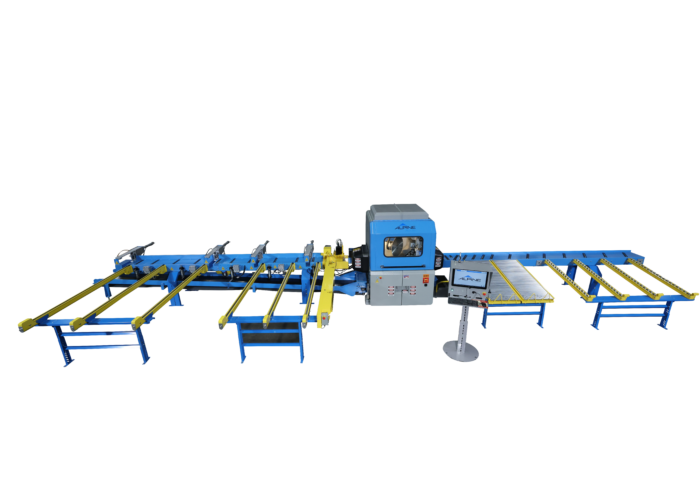

Alpine® Linear Saw 5.0

Building on reliability and accuracy, the latest version of the linear saw is engineered to meet the demands of today’s component manufacturers. The Alpine® Linear Saw 5.0 (ALS 5.0) offers the potential for significant increases in production throughput with overall speed enhancements and optimized workflows. The cutting workflow puts the sawyer in control with an optional automatic double-stacking of identical components as well as a synchronized infeed/outfeed motion, maximizing lumber throughput while reducing waste.

Standard Footprint: 42’– 8” x 12’–10” (W x L)

*as shown

Maximize Throughput

The ALS 5.0 configuration is system engineered to speed up production and output.

Operational Efficiency

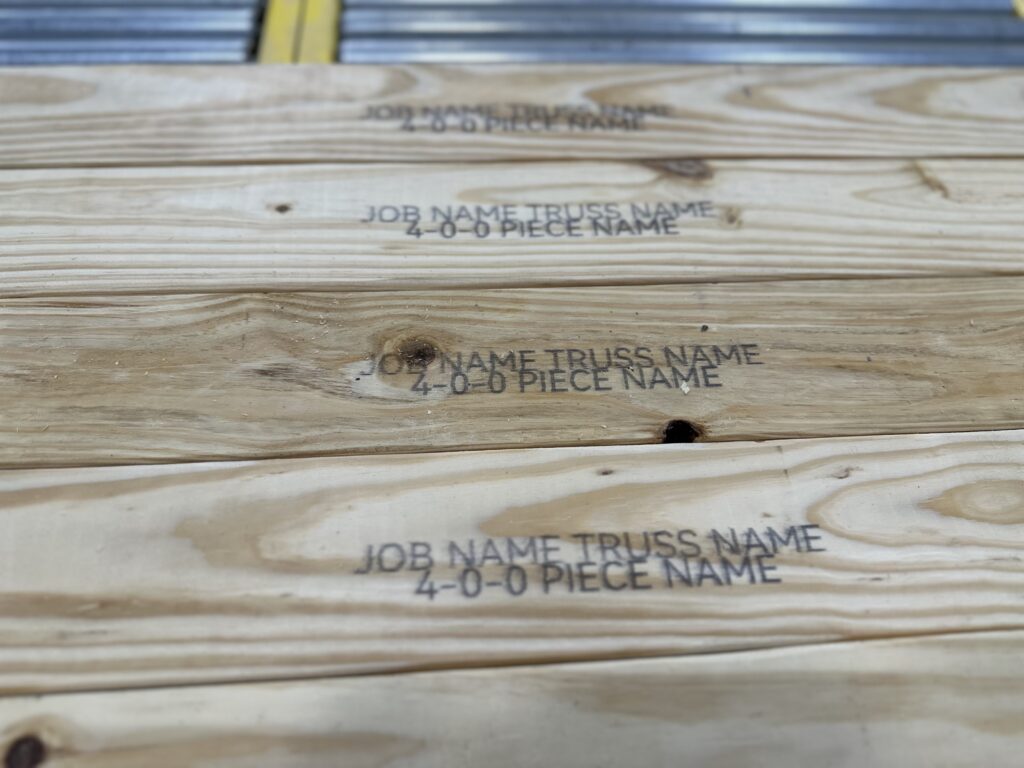

Equipped with a small parts handler and high-resolution printing to achieve optimal truss assembly.

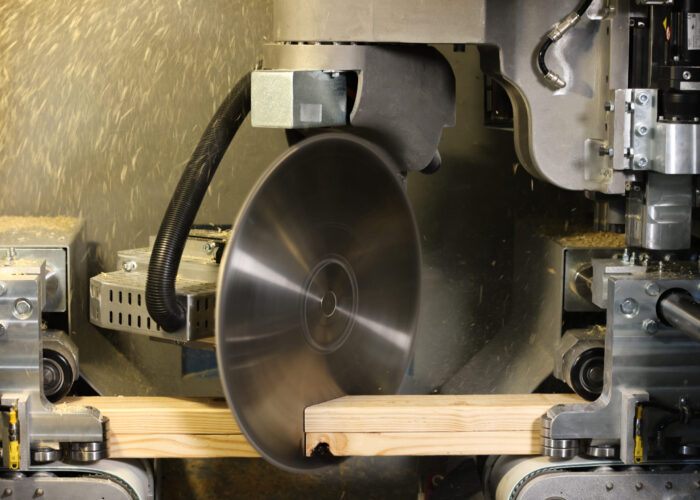

Reliable &

Accurate

Cutting up to 1/16 of an inch, reducing re-cuts and maximizing productivity.

Features

-

Small parts delivered directly to outfeed conveyor

The ALS 5.0 small parts handler eliminates the need for manual sorting, transferring small components directly to the outfeed conveyor. Small parts and truss components exit the saw to a common point, optimizing stacking efficiency for the sawyer and improving overall ergonomics.

-

High resolution printing for face and edge of lumber

Equipped with a high-resolution printing system, the Alpine Linear Saw marks the lumber, allowing for easy sorting and quick piece identification.

-

Synchronized infeed/outfeed motion

Maintain a steady supply of lumber to the saw with the synchronized infeed/outfeed system. The constant lumber feeding system reduces pauses between boards entering the saw cabinet, allowing for a continuous cutting state.

-

Print label shifting

The innovative print label shifting system allows for user-defined print alignment for printing on the center or end of lumber. Printing dynamically shifts for small parts, scaling the size of the label on the board to fit the needs of the sawyer.

-

New software platform

Get better optimization, set up nesting of components, automatic double stacking of like parts, and speed enhancements with the new ALS 5.0 software. The software is redesigned to offer the user an unmatched experience.

-

Board length scanner

The ALS 5.0 ensures all boards are the correct length before entering the saw, eliminating incorrect cuts and sizing errors.

-

Front/rear facing outfeed

Customizable saw configuration designed to fit any plant layout.

-

8' Infeed with automated live deck

The 8′ infeed continuously feeds lumber into the saw, ensuring minimization of downtime and increasing productivity, allowing for the stacking of 26 2’×4′ boards.

-

Intuitive, easy to use operator workstation

The updated user interface is designed for an easy and quick to learn user experience.

-

Product support

Our equipment is backed by a highly trained support team ready to assist you with any specific equipment needs. Please call (800) 755-6005 or email our experts at machinerysupport@alpineitw.com for onsite service or technical phone support.

Specifications

| Lumber Size Range | Min | Max | |

|---|---|---|---|

| Width | 2.38”(64mm) | 14”(355mm) | |

| Thickness | 1.38”(35mm) | 1.77”(45mm) | |

| Length | 36”(915mm) | 24’(without additional support) | |

| Chords • Webs • Scissor bottom chords • Wedges • Sliders |

| Single and double beveled ends (when equipped with optional bevel axis) |

| Ripped valley bottom chords (when saw is equipped with optional bevel axis) |

| Floor truss webs (when saw is equipped with optional bevel axis) |

| Standard Footprint | 42′-8′ x 12′-10′(W x L) | |

|---|---|---|

| Weight | 9,900 lbs | |

| Saw Blade | Diameter | Custom 20.5″ |

| Blade Motor | Max RPM | 2800 rpm |

| Infeed (L1-axis) |

Accuracy Max Speed |

±0.0625” 900 ft/min |

| Outfeed (L2-axis) |

Accuracy Max Speed |

±0.0625” 900 ft/min |

| Translation Cutting (L1-T1) | Max Speed | 28 in/sec |

| Angle (A-axis) |

Travel Accuracy |

0° to 300° ±0.1° |

| Bevel (optional) (B-axis) |

Travel Accuracy |

5° to 70° ±0.1° |

| Traverse (T-axis) |

Travel Accuracy |

-10” to +14” 0° references the fence |

| Vertical (Z-axis) |

Travel Max Speed |

7.5” 13 in/sec |

| Controller |

PC Monitor Communications |

Industrial PC w/Enterprise LTSC System 22” flat panel touchscreen Ethernet |

| Operating Temperature | 41°F to 104°F | |

| Foundation Requirement | ≥4” thick reinforced concrete | |

| Voltage Draw | 480VAC 3PH 70A, 60Hz/FLA 65 A @ 460VAC | |

| Air Draw | 45 CFM @100 PSI |

| Intuitive double stacking with bow detection |

| Plate layout and jig marking |

| Wall panel printing |

| 16′ infeed with automated live deck |

| Beveling axis |

| Wood retrieval system |

| Right to left configuration |

| Waste incline conveyor |

| Maintenance Suite |

| 275, 276, 286, 4.0, 5.0 |

| Emergency Stop | Pushbuttons |

|---|---|

| Interlock | Safety rated interlock on front door |

| Safety Compliance | ETL listed panels |

| Labeling | Trilingual (English, Spanish, French) |

| Saw blade | Enclosed cutting area |