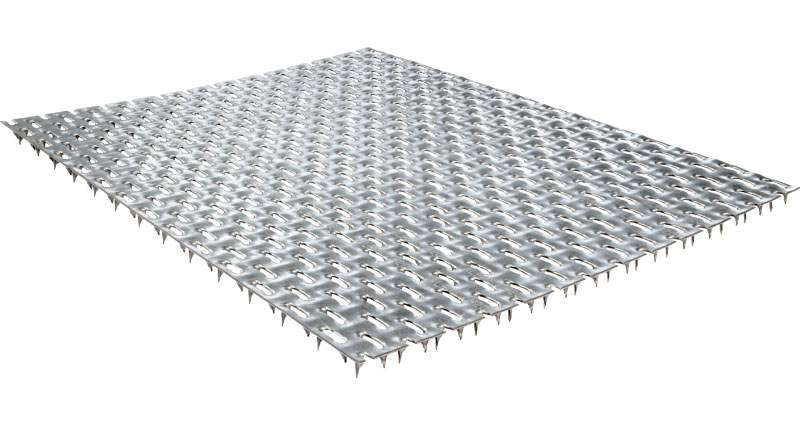

Wave Plate

- The most popular connector plate.

- Offers the highest performance levels in side-by-side comparison tests with all other competitive products.

- Can be rolled or hydraulically pressed.

- Uses Grade 40 steel – a higher grade than previous plates – so it provides superior plate values.

- Alpine spent more than one and a half years researching, developing and testing the Wave Plate before its introduction.

Specifications

Steel Properties

| Thickness | 20 gauge |

|---|---|

| Grade | 40 |

| Teeth/ sq. In. | 8 |

Size Range*

| Width | 1” to 12” |

|---|---|

| Length | 2” to 24” |

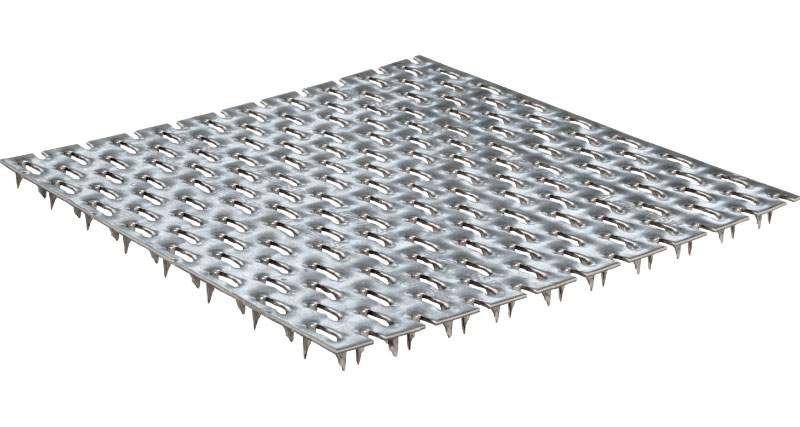

“H” High-Strength 20 Gauge Plate

- The “H” High-Strength 20 Gauge Plate delivers increased tension values for use in splice joints and other high-stress connections.

- Uses Grade 60 steel, a grade that is stronger than the steel used for the Wave Plate.

- Tooth length matches the tooth length of the Wave Plate, which is important for roller press compatibility in truss production.

- The “H” High-Strength 20 Gauge Plate was previously known as the “HS” Plate.

Specifications

Steel Properties

| Thickness | 20 gauge |

|---|---|

| Grade | 60 |

| Teeth/ sq. In. | 7 |

Size Range*

| Width | 3.2″ to 13.1″ |

|---|---|

| Length | 8.7″ to 24.5″ |

“SS” Super-Strength 18 Gauge Plate

- Development of the “SS” Super-Strength 18 Gauge Plate was driven by the increased availability of high-performance lumber.

- Delivers higher steel capacities in tension for splicing.

- Uses Grade 60 steel and its tooth length matches the Wave Plate for roller press compatibility.

- Has the highest tension value of all connector plates.

Specifications

Steel Properties

| Thickness | 18 gauge |

|---|---|

| Grade | 60 |

| Teeth/ sq. In. | 7 |

Size Range*

| Width | 3.2″ to 13.1″ |

|---|---|

| Length | 7.0″ to 24.5″ |

Hinge Plate

- The 18 gauge Hinge Plate, primarily utilized in the manufactured housing industry, uses Grade 40 steel for superior tension and compression values.

- When used on the top chord of the truss, the Hinge Plate permits the chord to be folded down for transportation and then raised in place onsite.

- Can also be used to eliminate the need for piggyback trusses.

- In side-by-side comparisons, the Hinge Plate meets or exceeds the compression values of competitive products.

Specifications

Steel Properties*

| Thickness * | 18 gauge |

|---|---|

| Grade | 40 |

| Teeth/ sq. In. | 8 * |

Size Range **

| Width | 2″ |

|---|---|

| Length | 8″ |

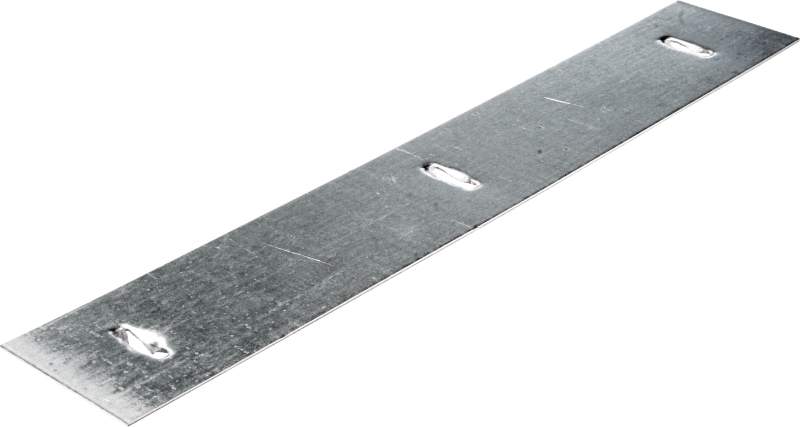

Seat Plate

- Used as a moisture barrier to help provide a break between the wood truss and concrete or masonry

- Prevents the wicking of water into the wood

- Attached to the bottom chord of the truss at bearing points

- Available with teeth in 20 Gauge Steel

Specifications

Steel Properties *

| Thickness * | 20 gauge |

|---|---|

| Grade | CS |

| Teeth | 3 pairs |

Size Range

| Width | 1.37″ |

|---|---|

| Length | 8″ |